DTF Apparel Printing (Direct to Fabric) is an innovative process creating custom logos and artwork directly on fabrics with exceptional detail and vibrancy, replacing traditional screen printing. This technology revolutionizes garment production, enabling quick, efficient, high-quality personalized printing across diverse fabric types and colors. Businesses can offer unique, on-demand services, enhancing brand visibility in a competitive market. The meticulous art involves designers creating visuals in specialized software, followed by precise ink application, careful fabric selection, and heat press settings to ensure outstanding results, turning garments into branded canvases for promotional or personal use.

“Unleash your brand’s potential with DTF Apparel Printing—a game-changing technology transforming the way you create custom logos and artwork. This innovative process allows for precise, vibrant printing directly on various fabrics, from t-shirts to hoodies. In this article, we’ll explore the fundamentals of DTF (Direct-to-Garment) printing, its myriad advantages, and walk you through the entire workflow, ensuring your designs jump off the fabric. Discover how DTF Apparel Printing is revolutionizing personalized merchandising.”

- Understanding DTF Apparel Printing: The Basics

- Benefits of Print Custom Logos and Artwork with DTF Apparel Printing

- The Process: From Design to Final Product using DTF Apparel Printing Techniques

Understanding DTF Apparel Printing: The Basics

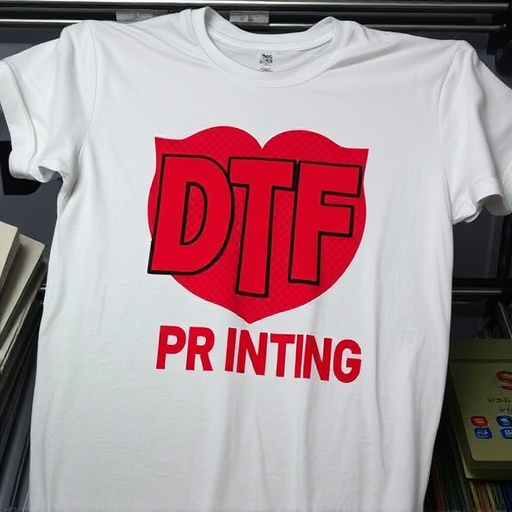

DTF Apparel Printing, or Direct to Fabric (DTF) printing, is a cutting-edge method that allows for the creation of custom logos and artwork directly onto various fabrics. Unlike traditional screen printing methods that require separate screens for each color, DTF utilizes a digital process to transfer designs with exceptional detail and vibrancy. This innovative technique has revolutionized the apparel industry by enabling businesses and designers to produce high-quality, personalized garments quickly and efficiently.

The process begins with creating or sourcing dtf artwork transfers—digitally printed images that serve as templates for the design. DTF printers then use specialized heat presses to apply these transfers onto fabrics, ensuring precise color matching and vibrant results. This method accommodates a wide range of fabric types and colors, making it suitable for everything from t-shirts and hoodies to hats and bags. By leveraging DTF technology, businesses can offer unique, on-demand printing services, catering to diverse customer preferences and creating a competitive edge in the market.

Benefits of Print Custom Logos and Artwork with DTF Apparel Printing

Print Custom Logos and Artwork with DTF Apparel Printing offers a multitude of benefits for businesses and designers alike. One of the key advantages is the ability to create high-quality, vibrant prints on a variety of fabrics and materials, ensuring your branding stands out in a crowded market. DTF (Direct to Fabric) technology allows for precise and detailed designs, making it perfect for intricate logos and complex artwork.

Additionally, DTF Apparel Printing facilitates efficient production processes. With user-friendly tools like the dtf gang sheet builder, creating and organizing print layouts is simple and quick. This streamlines the workflow, reducing turnaround times without compromising on quality. Moreover, understanding the appropriate dtf heat transfers application instructions ensures consistent and professional results, making it an accessible option for both beginners and seasoned professionals.

The Process: From Design to Final Product using DTF Apparel Printing Techniques

The process of creating printed custom logos and artwork with DTF Apparel Printing is an art in itself. It begins with designers crafting unique visuals that capture the brand’s essence, utilizing cutting-edge graphic design software. These designs are then meticulously prepared for printing, ensuring they meet the specifications required for DTF (Direct to Garment) techniques. The heart of the process involves the DTF Apparel Printing technology, where advanced machines precisely apply ink directly onto the garment surface, offering exceptional detail and color accuracy.

Once the design is finalized, it’s time to choose the appropriate fabric and garment style for your dtf custom orders. Setting the dtf heat press settings correctly is crucial to achieving a high-quality finish. The printed garments then undergo careful quality checks to ensure they meet the desired standards. This meticulous approach ensures that each piece of apparel becomes a unique canvas, showcasing the client’s vision and brand identity, be it for promotional purposes or personal style expressions.

DTF (Direct-to-Fabric) apparel printing is a game-changer for businesses seeking high-quality, custom logo and artwork solutions. By embracing this innovative technique, companies can offer durable and visually appealing products while streamlining their production process. With its precision, versatility, and ability to produce vibrant, indelible designs, DTF printing revolutionizes the way we approach apparel customization. This efficient method ensures that brands can meet demand promptly, providing a seamless experience for both businesses and consumers alike.