DTF Apparel Printing is a cutting-edge method for custom graphics on clothing, using heat and pressure to bypass screen printing. This technique offers versatility across fabrics, faster production times, and vibrant finishes, ideal for creating unique DTF graphic tees. Heat press finishing enhances durability and quality, especially for dark fabrics. Integrating DTF with heat press finishing, through meticulous preparation and best practices, yields exceptional design aesthetics and durable garments suitable for bulk DTF shirt production.

Discover the power of combining DTF Apparel Printing with Heat Press Finishing for unparalleled results. This innovative approach offers precise, vibrant prints on a wide range of fabrics, ensuring durability and quality. In this comprehensive guide, we’ll explore the techniques and benefits of DTF printing, delve into the heat press process, and share best practices to integrate these methods seamlessly. Elevate your apparel design with DTF – the future of printing is here.

- Understanding DTF Apparel Printing: Techniques and Benefits

- Heat Press Finishing: Enhancing Print Quality and Durability

- Integrating Processes: Best Practices for Seamless Results

Understanding DTF Apparel Printing: Techniques and Benefits

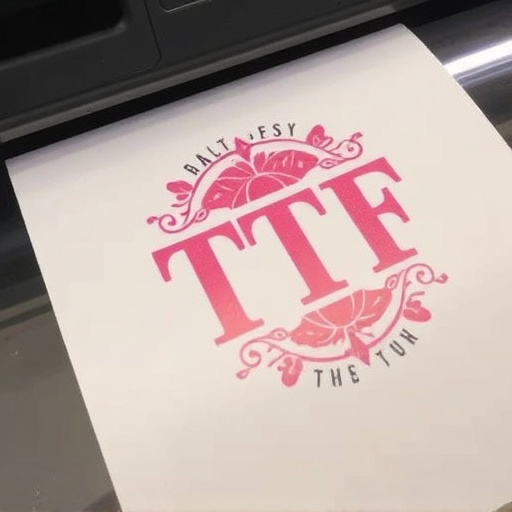

DTF Apparel Printing, or Direct-to-Fabric Transfer, is a cutting-edge technique revolutionizing the way custom graphics are applied to clothing. This innovative process eliminates the need for traditional screen printing methods by using heat and pressure to transfer designs directly onto fabric. With DTF, businesses can create stunning, high-quality custom dtf transfers for DTF printing of Custom graphic tees and other apparel items.

One of the key benefits of DTF Apparel Printing is its versatility; it can be used on a wide range of fabrics and materials, including cotton, polyester, and even nylon. This makes it an excellent choice for those looking to create unique, personalized DTF for Custom graphic tees that stand out from the crowd. The technique also offers faster production times compared to traditional printing methods, allowing businesses to meet demand promptly. Moreover, DTF provides a crisp, vibrant finish, ensuring designs are durable and remain intact even after multiple washes.

Heat Press Finishing: Enhancing Print Quality and Durability

Heat Press Finishing is an essential step that significantly enhances the quality and durability of DTF Apparel Printing. This technique involves using a heat press machine to apply pressure and heat to the printed design, fusing it permanently onto the fabric. It’s particularly effective for dtf heat transfer paper designed for dark fabrics, ensuring vibrant and precise color reproduction even on challenging surfaces.

This process not only secures the print but also adds a professional finish to garments, making them more durable and suitable for prolonged use. For clothing brands looking to create high-quality, long-lasting apparel, dtf printing for dark fabrics combined with heat press finishing is an indispensable combination. This method allows brands to deliver on their promise of robust, stylish clothing that stands the test of time and washing machines alike.

Integrating Processes: Best Practices for Seamless Results

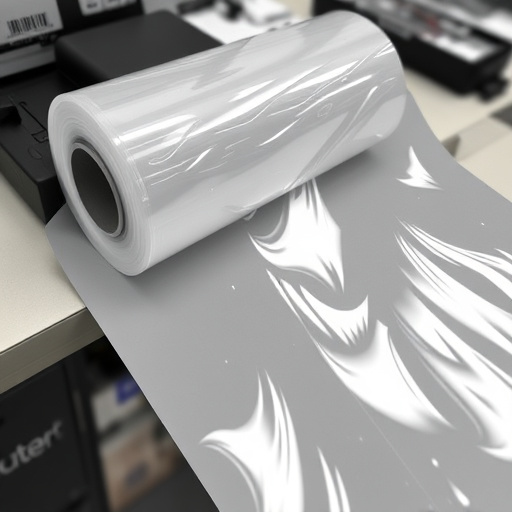

Integrating DTF (Direct to Fabric) Apparel Printing with Heat Press Finishing is a game-changer for clothing manufacturers. The process begins with precise preparation, ensuring the design’s accuracy on the dtf transfer film. This film acts as a guide, allowing printers to achieve intricate details and vibrant colors on various fabrics. Once printed, the dtf transfer is carefully applied to the garment, creating a temporary layer that will later be permanently set by the heat press machine.

Best practices include using high-quality inks and films suitable for the fabric type, as this guarantees a long-lasting finish. Precise temperature and pressure settings during the heat press are crucial for seamless results, preventing smudges or uneven application of the design. Efficient workflow management is also key; proper drying time allows the ink to set properly before handling, ensuring the final product meets the desired quality standards. This seamless integration ensures that the printed designs not only look exceptional but also withstand the rigors of everyday use, making it a popular choice for bulk dft shirt production.

DTF Apparel Printing, with its advanced techniques and benefits, combined with Heat Press Finishing, offers a powerful solution for enhancing print quality and durability. By seamlessly integrating these processes, manufacturers can achieve exceptional results, ensuring their apparel stands out in the market while maintaining superior craftsmanship. This innovative approach to garment printing is sure to revolutionize the industry, providing both style and substance.